COMPANY

About Porous Metal Filters, Inc.

About Porous Metal Filters, Inc.

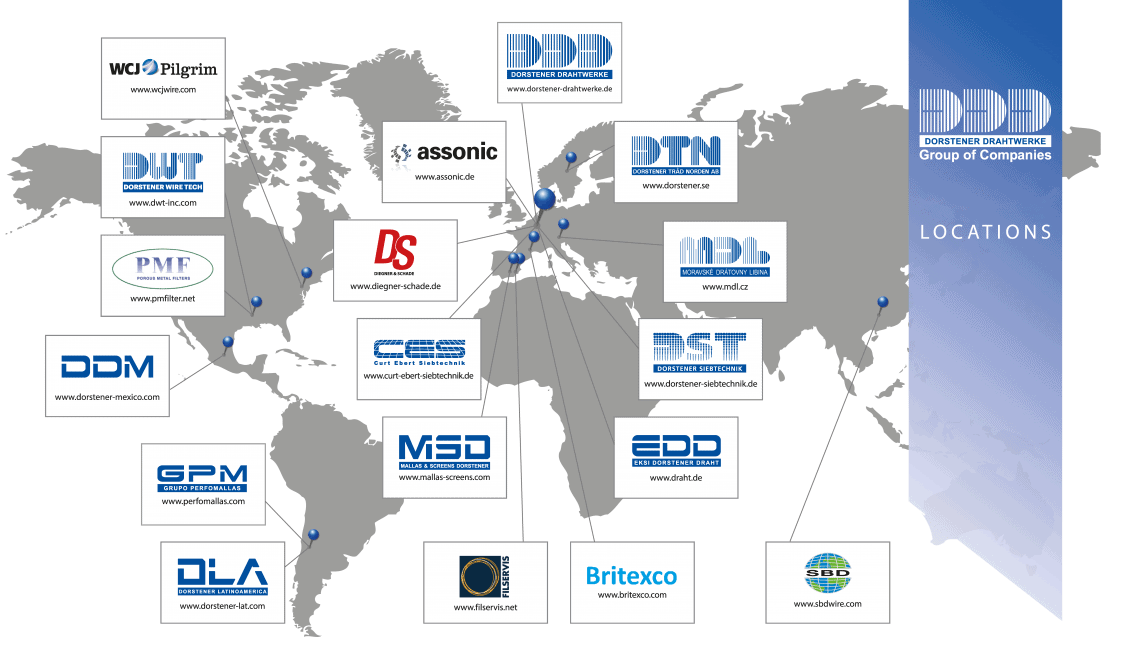

Porous Metal Filters, Inc. (PMF) is a leading provider of high-performance wire, wire cloth, welded mesh, and metal filter products. As part of the United States division of the Dorstener Group, PMF benefits from over 100 years of experience in the industry. Our SINTERPORE® brand offers diffusion bonded (sintered) porous metal materials that provide solutions for industrial filtration, separation, flow control, noise reduction, powder fluidization, and more. With a wide range of micron ratings, permeability, and alloys available, our SINTERPORE® filter elements cartridges ensure optimum filtration in various applications. Count on PMF to deliver cutting-edge porous metal filter technology for your filtration and separation needs. Contact us today to learn more!

Porous metal filter elements have proven to be bleeding-edge technology widely practiced in many industries from clarification of natural fruit juices to water treatment and waste streams containing detergents, polymers, and organic solvents.

SINTERPORE® filter elements cartridges are available in a broad range of micron ratings, permeability, and alloys.

The History of Porous Metal Filters, Inc.

Porous Metal Filter Inc. (PMF), was established in 2008, has a collective knowledge from over 120 years of experience in porous metal filter media, filtration experience, and fabrication of filtration products. The goal of Porous Metal Filters is to utilize this experience to promote the use of porous metal media in the next generation of advanced filtration and separation products.

At Porous Metal Filters, we manufacture diffusion-bonded porous metal sheets, multi-layered laminate filter media, fabricated filtration elements, leaves, cylinders, cones and more. The Porous Metal Filters SinterPore® product offerings of SLS (single layer sintered), MLS (multi-layer sintered), and CLS (custom layer sintered) are comprised of single and multiple layers of woven stainless wire mesh, non-woven metallic fibers, and perforated sheet and foils. This is used for filtration, separation, flow control, noise reduction, powder fluidization, and many other uses.

The standard materials of construction are 304, 304L, 316, 316L stainless steel. Custom materials such as Alloy 20, Hastelloy C-22 and 276, Monel, and Inconel 600 and 625 are available upon request.

The SinterPore® materials are designed for high-temperature and corrosive environments where the controlled pore size, pore geometry, and permeability characteristics are a prerequisite for optimum filtration. These properties are required in a variety of applications including aerospace, automotive, chemical, pharmaceutical, polymer, food & beverage, oil & gas, and power generation industries.

In addition to filtration media and element manufacture, Porous Metal Filters offers consulting and engineering services including product testing, process evaluation/optimization, and training in filtration principles.

At Porous Metal Filters, we manufacture products to the highest current industry standard and are certified to meet ISO 9001 requirements.

Contact us today to learn more!

Our mission is to provide our clients with the best possible solution at a price that fits your budget. This solution incorporates all aspects of our clients needs; budget constraints, delivery requirements, product expectations and a back up plan for emergency situations.

Quality Assurance

Porous Metal Filter manufactures a wide range of woven wire cloth, welded wire mesh and filtration products for hundreds of applications in almost every industry.

Our clients require products for applications from aerospace and medical to construction and safety mesh. PMF’s quality assurance processes are designed to ensure that the specifications for each product and application are met, and our clients are delivered the product they require.

Porous Metal Filters is ISO 9001 certified and all our manufacturing processes meet the highest quality standards. All products can be manufactured in accordance with the DIN, ASTM and ISO standards required by our clients. In addition, PMF’s woven wire cloth and welded wire mesh products can be ordered to meet DFAR and other military standards.

PMF is committed to providing our clients with wire products that meet their requirements and are cost effective, allowing for problem-free production runs when producing the end product. Our staff works closely with each client to ensure that the products we supply meet or exceed expectations. Porous Metal Filters is the leading metal mesh manufacturer and supplier in the United States.

AFFILIATIONS

American Filtration & Separations Society

A technical educational nonprofit organization started in 1987 to provide a forum for exchange of information among engineers, scientists, and technologists in all areas of the fluid/particle separation field.

The American Wire Cloth Institute

The American Wire Cloth Institute was founded in 1933 by a group of wire cloth producers interested in furthering good business practices and assuring a healthy future for this vital industry.

Your One-Stop Solution for Advanced Filtration and Metal Fabrication

We invite you to explore and discover how PMF can transform your filtration and separation challenges into opportunities for growth and success. Join us on this exciting journey as we reshape industries, one innovative filter at a time. Together, let's unlock the true potential of porous metal filtration. Give us a call, stop by for a free tour of the facility, or fill out our contact form and we'll gladly assist you.

Find Exactly What You Need

COMPANY

INDUSTRIES & APPLICATIONS

Automotive

Bulk & Powder Handling

Chemical Processing

Chromatography

Crude Oil Processing

Filtration Industry

Fuel Cells & Re-Formers

Gasification

Hot Gas Filtration

Industrial Filtration

Industrial Water Management

Irrigation Filtration

Liquid Filtration

Noise Abatement

Oil & Gas

Pharmaceutical

Plant Oil Extraction

Power Generation

Renewable Energy

Aerospace Filters

Ballast Water Filters

Chemical & Industrial Spargers

Chromatography Frits

Demineralizer Filters

Flame/Spark Arrestors

Flood Filters

Fluidizing Media

Gasification Filters

Hot Gas Filters

Irrigation Filters

Metallic Filter Cartridges

Metallic Memberane Support for Hydrogen

Nutsche Filters

Porous Metal Plate

Sand Screens

Sintered Metal Fiber

Sintered Wire Cloth

Temporary Strainers & Baskets

CAPABILITIES

Thanksgiving Holiday:

Closed Nov 27, 28

Christmas Holiday:

New Year Holiday:

Porous Metal Filters provides solutions for industrial filtration, separation, flow control, noise reduction, powder fluidization, and other applications through our SINTERPORE® brand of diffusion bonded (sintered) porous metal materials. Porous Metal Filters’ goal is to utilize its extensive experience to promote porous metal filters for the next generation of advanced filtration and separation products.

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(833) 707-9222 toll free

(281) 719-1352 local

(281) 719-1351 fax