MANUFACTURING CAPABILITIES

Welding Services

Welding Services for Wire Cloth and Wire Mesh Products

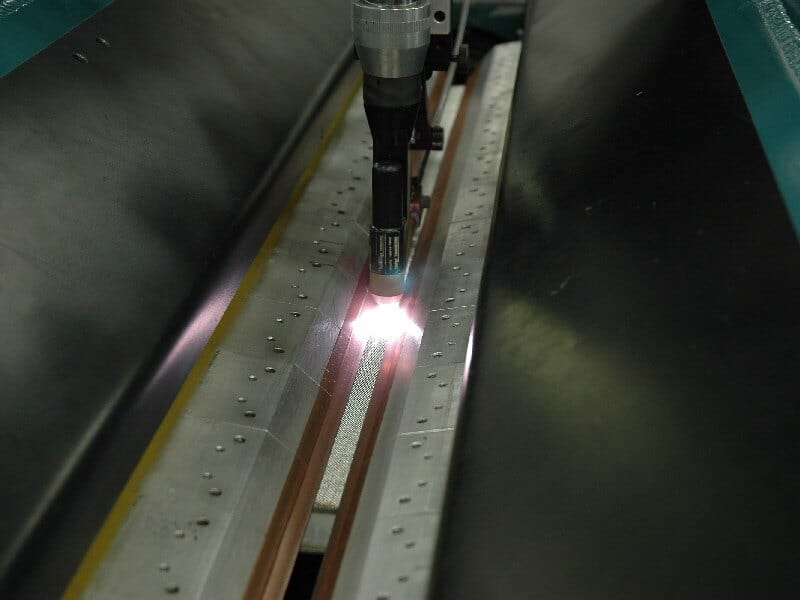

Wire cloth can be welded together to form a wide array of filters, guards, filters and screens. Porous Metal Filters provides resistance, TIG and plasma welding services for woven wire mesh and diffusion bond wire cloth. We can provide you a production-ready finished product, saving production time and cost.

Resistance welded parts are commonly used in disposable wire cloth filters. Common applications include spot weld packs for the plastic extrusion process. This eliminates the handling of individual screens.

Our TIG and plasma welding services for wire cloth filters are second to none. We primarily weld nickel based alloys in 304, 316, 904L, Alloy 20 and many more. Welding of sintered wire cloth requires a special skill set and specialized equipment. We work in challenging industries where welds are critical. Oil and gas, ballast water, and petrochemical applications are our specialty.

Custom Welding Services

Our expert staff and welding equipment will work with you from the manufacture of the wire cloth or mesh through finishing and welding. Our quality control and inspection services will ensure that the welded mesh product we deliver meets your exact requirements.

Welding Services by Porous Metal Filters

Porous Metal Filters is ISO 9001 Certified, and all our products are manufactured to the highest quality standards. Our staff is available to help you design the wire filtration product that will meet your design requirements and budget. Contact us today for more information about our products.

Your One-Stop Solution for Advanced Filtration and Metal Fabrication

We invite you to explore and discover how PMF can transform your filtration and separation challenges into opportunities for growth and success. Join us on this exciting journey as we reshape industries, one innovative filter at a time. Together, let's unlock the true potential of porous metal filtration. Give us a call, stop by for a free tour of the facility, or fill out our contact form and we'll gladly assist you.

Find Exactly What You Need

COMPANY

INDUSTRIES & APPLICATIONS

Automotive

Bulk & Powder Handling

Chemical Processing

Chromatography

Crude Oil Processing

Filtration Industry

Fuel Cells & Re-Formers

Gasification

Hot Gas Filtration

Industrial Filtration

Industrial Water Management

Irrigation Filtration

Liquid Filtration

Noise Abatement

Oil & Gas

Pharmaceutical

Plant Oil Extraction

Power Generation

Renewable Energy

Aerospace Filters

Ballast Water Filters

Chemical & Industrial Spargers

Chromatography Frits

Demineralizer Filters

Flame/Spark Arrestors

Flood Filters

Fluidizing Media

Gasification Filters

Hot Gas Filters

Irrigation Filters

Metallic Filter Cartridges

Metallic Memberane Support for Hydrogen

Nutsche Filters

Porous Metal Plate

Sand Screens

Sintered Metal Fiber

Sintered Wire Cloth

Temporary Strainers & Baskets

CAPABILITIES

Thanksgiving Holiday:

Closed Nov 27, 28

Christmas Holiday:

New Year Holiday:

Porous Metal Filters provides solutions for industrial filtration, separation, flow control, noise reduction, powder fluidization, and other applications through our SINTERPORE® brand of diffusion bonded (sintered) porous metal materials. Porous Metal Filters’ goal is to utilize its extensive experience to promote porous metal filters for the next generation of advanced filtration and separation products.

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(833) 707-9222 toll free

(281) 719-1352 local

(281) 719-1351 fax