INDUSTRIES & APPLICATIONS

Industrial Water Management

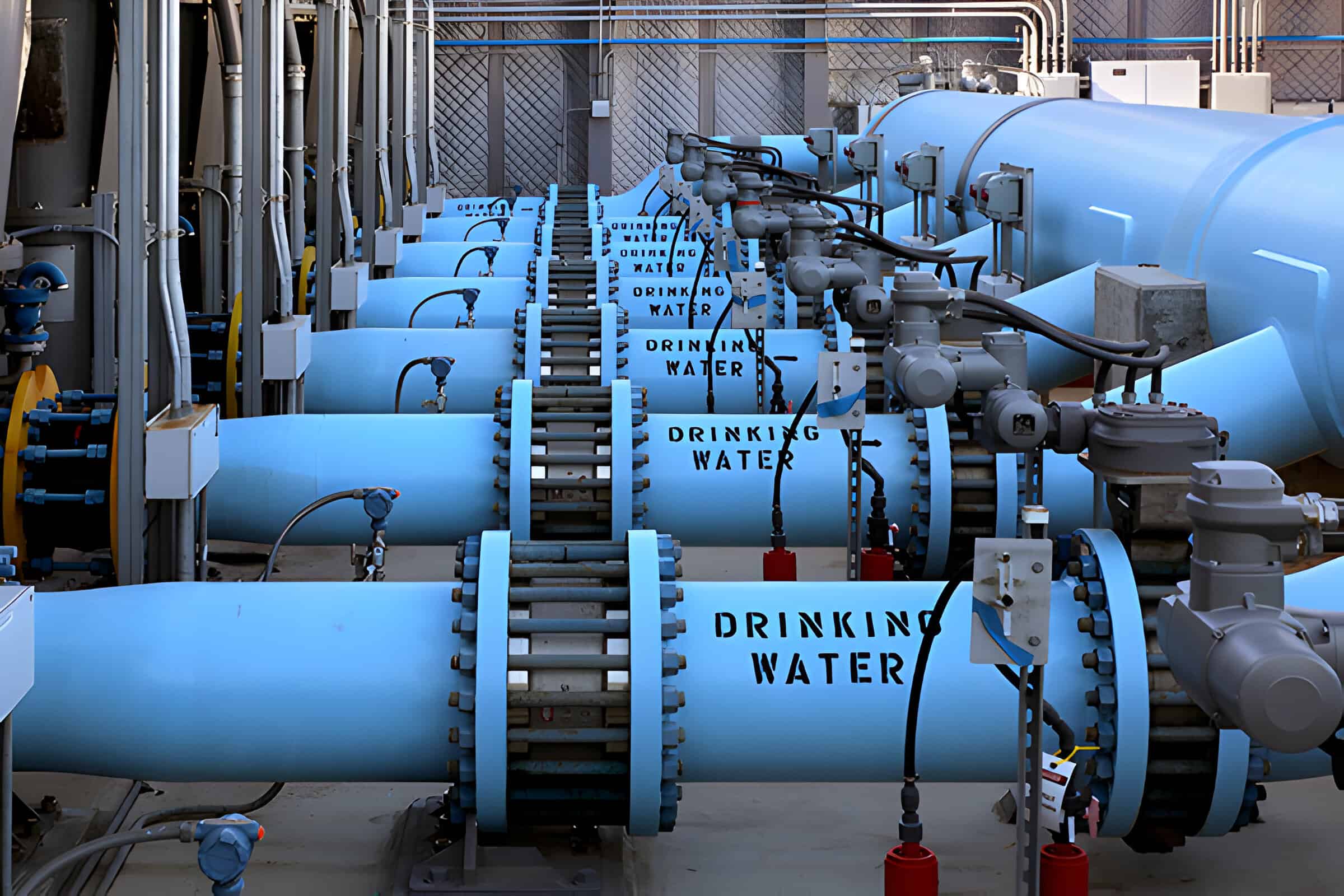

Transforming Industrial Water Management with Advanced Filtration Solutions

We understand the diverse needs of the water treatment industry and offer a comprehensive range of filters and filter media to address various water management applications. From desalination to wastewater treatment, our advanced products play a vital role in ensuring efficient and sustainable water management.

Porous Metal Filters products for Industrial Water Management applications include Chemical and Industrial Spargers, Demineralizer Filters, Flood Filters, Metallic Filter Cartridges, and Temporary Strainers and Baskets.

Enhancing Water Treatment in Various Water Management Industries

Desalination is a critical process in water treatment, and our filtration solutions play a key role in facilitating the reuse of seawater in industrial processes and even for drinking water production. By effectively removing impurities and contaminants, our filters contribute to sustainable water management practices and support the conservation of freshwater resources.

In the industrial water sector, we optimize water usage in various applications such as beverage production, parts washing, and paper production. By implementing our advanced filtration solutions, industries can conserve water resources, minimize environmental impact, and ensure the efficient use of water throughout their processes.

Efficient irrigation practices are vital for sustainable agriculture, and our filters play a crucial role in enabling water reuse for landscaping and the growth of fresh crops. By effectively treating water and removing impurities, our filtration solutions contribute to efficient irrigation systems, reducing the strain on freshwater resources and promoting responsible water management in agriculture.

In the municipal water sector, our filtration products ensure the production of high-quality potable water that meets stringent regulations. We provide reliable filtration solutions that remove contaminants, ensuring the safety and purity of drinking water for communities. With our advanced technology, we support municipal water treatment facilities in delivering clean and safe water to the public.

Contact us today to discuss your specific requirements and discover how our filters and filter media can transform your water treatment operations. Together, let’s achieve superior industrial water management with advanced filtration excellence.

Porous Metal Filters is ISO 9001 Certified, and all our products are manufactured to the highest quality standards. Our staff is available to help you design the wire filtration product that will meet your design requirements and budget. Contact us today for more information about our products.

Your One-Stop Solution for Advanced Filtration and Metal Fabrication

We invite you to explore and discover how PMF can transform your filtration and separation challenges into opportunities for growth and success. Join us on this exciting journey as we reshape industries, one innovative filter at a time. Together, let's unlock the true potential of porous metal filtration. Give us a call, stop by for a free tour of the facility, or fill out our contact form and we'll gladly assist you.

Find Exactly What You Need

COMPANY

INDUSTRIES & APPLICATIONS

Automotive

Bulk & Powder Handling

Chemical Processing

Chromatography

Crude Oil Processing

Filtration Industry

Fuel Cells & Re-Formers

Gasification

Hot Gas Filtration

Industrial Filtration

Industrial Water Management

Irrigation Filtration

Liquid Filtration

Noise Abatement

Oil & Gas

Pharmaceutical

Plant Oil Extraction

Power Generation

Renewable Energy

Aerospace Filters

Ballast Water Filters

Chemical & Industrial Spargers

Chromatography Frits

Demineralizer Filters

Flame/Spark Arrestors

Flood Filters

Fluidizing Media

Gasification Filters

Hot Gas Filters

Irrigation Filters

Metallic Filter Cartridges

Metallic Memberane Support for Hydrogen

Nutsche Filters

Porous Metal Plate

Sand Screens

Sintered Metal Fiber

Sintered Wire Cloth

Temporary Strainers & Baskets

CAPABILITIES

Porous Metal Filters provides solutions for industrial filtration, separation, flow control, noise reduction, powder fluidization, and other applications through our SINTERPORE® brand of diffusion bonded (sintered) porous metal materials. Porous Metal Filters’ goal is to utilize its extensive experience to promote porous metal filters for the next generation of advanced filtration and separation products.

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(833) 707-9222 toll free

(281) 719-1352 local

(281) 719-1351 fax