PRODUCTS

Fluidizing Media

Fluidizing Media Products

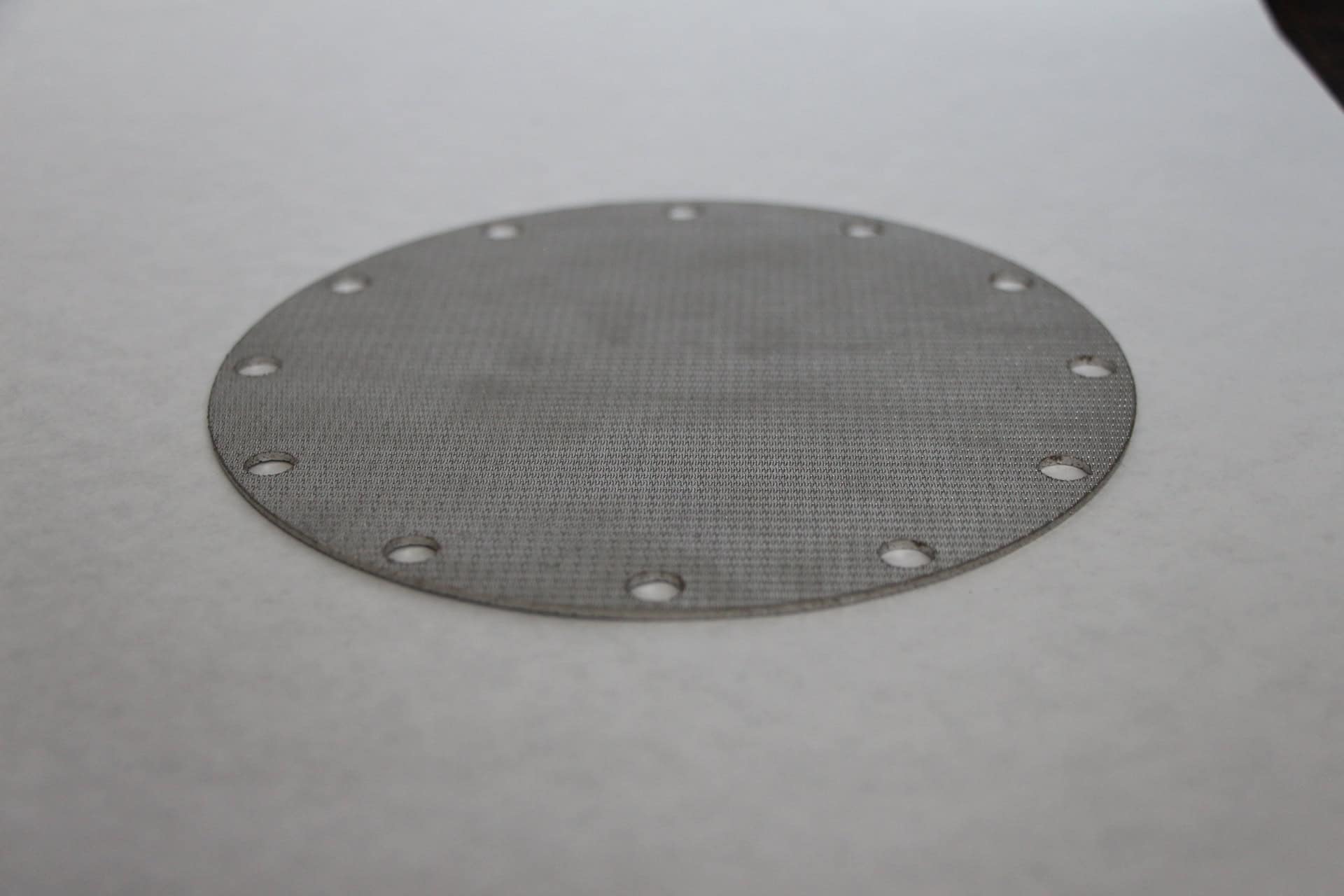

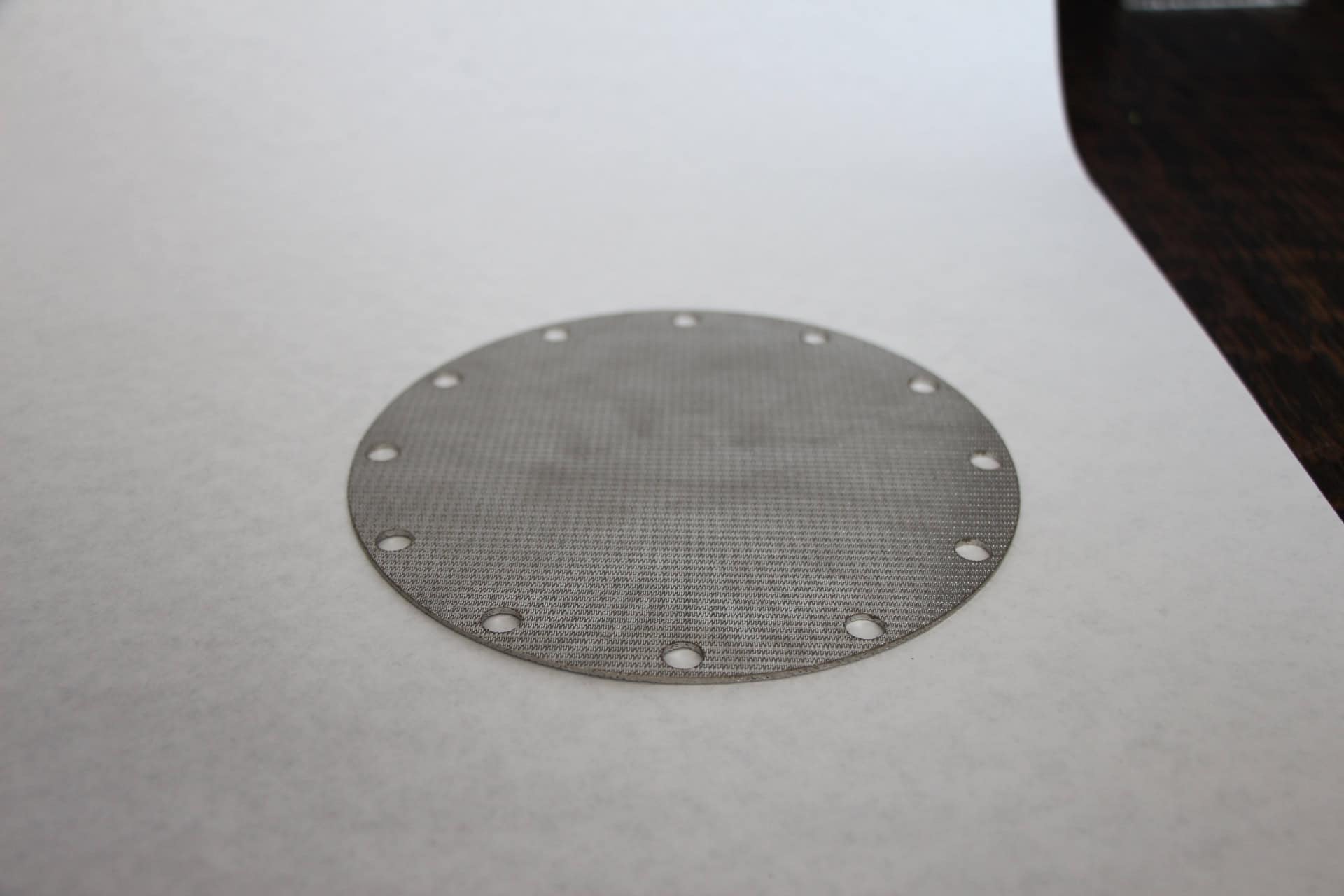

PMF’s SINTERPORE® fluidizing media is ideal for fluidized transport and handling of bulk powder materials. SINTERPORE® laminates are permanently bonded under precise diffusion bonding (sintering) conditions to yield robust monolithic materials used in a wide variety of fluidizing applications.

SINTERPORE® fluidizing media, multi-layered, diffusion bonded stainless steel mesh is available in 316L and other alloys. This precision fluidising media is available in low and high flow rates, to meet your application requirements.

Porour Metal Filters provides complete fabrication services for this material, including custom sizes, shapes, mounting holes and welding to end fittings or rings. We can also fabricate into tubes or fluidisation cones for hopper bottoms.

For fluidizing applications where a tightly controlled efficiency rating is required, Porous Metal Filters can provide a precision fine filter mesh (down to 2 microns nominal) sintered to the fluidising media.

This is particularly useful in reducing particulate bypass, clogging and when fluidising gas is not flowing constantly. SINTERPORE® fluidizing media is particularly suited to demanding applications where high operating temperatures of up to 540ºC (1000ºF), increased chemical or high abrasion resistance is essential, such as silo discharge cones, fluidized reactors and fluidized dryers.

This material is easily custom engineered to meet required specifications of materials, strength, flow requirements, thickness, micron rating and environment.

Porous Metal Filters Fluidizing Media Products are used in the Bulk and Powder Handling industry and the Pharmaceutical industry.

Features and Benefits of SINTERPORE® Fluidizing Media

The multilayer laminate construction results in a strong product with precisely controlled porosity, uniform pore sizes and distribution. The fluidizing media provides uniform distribution of gas and air flow for particulate fluidization and aeration.

- Cleanability

- Heat resistant / high operating temperatures

- Application and material versatility

- Enhanced chemical resistance

- Abrasion resistant

- Easily fabricated

- Uniform flow

- Fixed pore geometry

Fluidizing Media Applications

- Fluidizing beds

- Aerator for hoppers

- Air slides, rolls, and bearings

- Vacuum forming and molding

- Resin and catalyst beds

- Air gravity conveyors

- Flame and spark arrestors

- Spargers

Fluidizing Media Specifications

- Standard alloys: 304, 304L, 316, 316L, Alloy20 (also available in Inconel 600 and 625, Monel, and Hastalloy upon request).

- Operating temperature 1000 F.

- Standard sheet sizes: 18” x 48” and 20” x 48”. Custom sizes available upon request. Maximum laminate size without welding is 24”x 60” (larger sheets available with welds, maximum panel width with welds 120”).

Multi-Layer Diffusion Bonded Structure

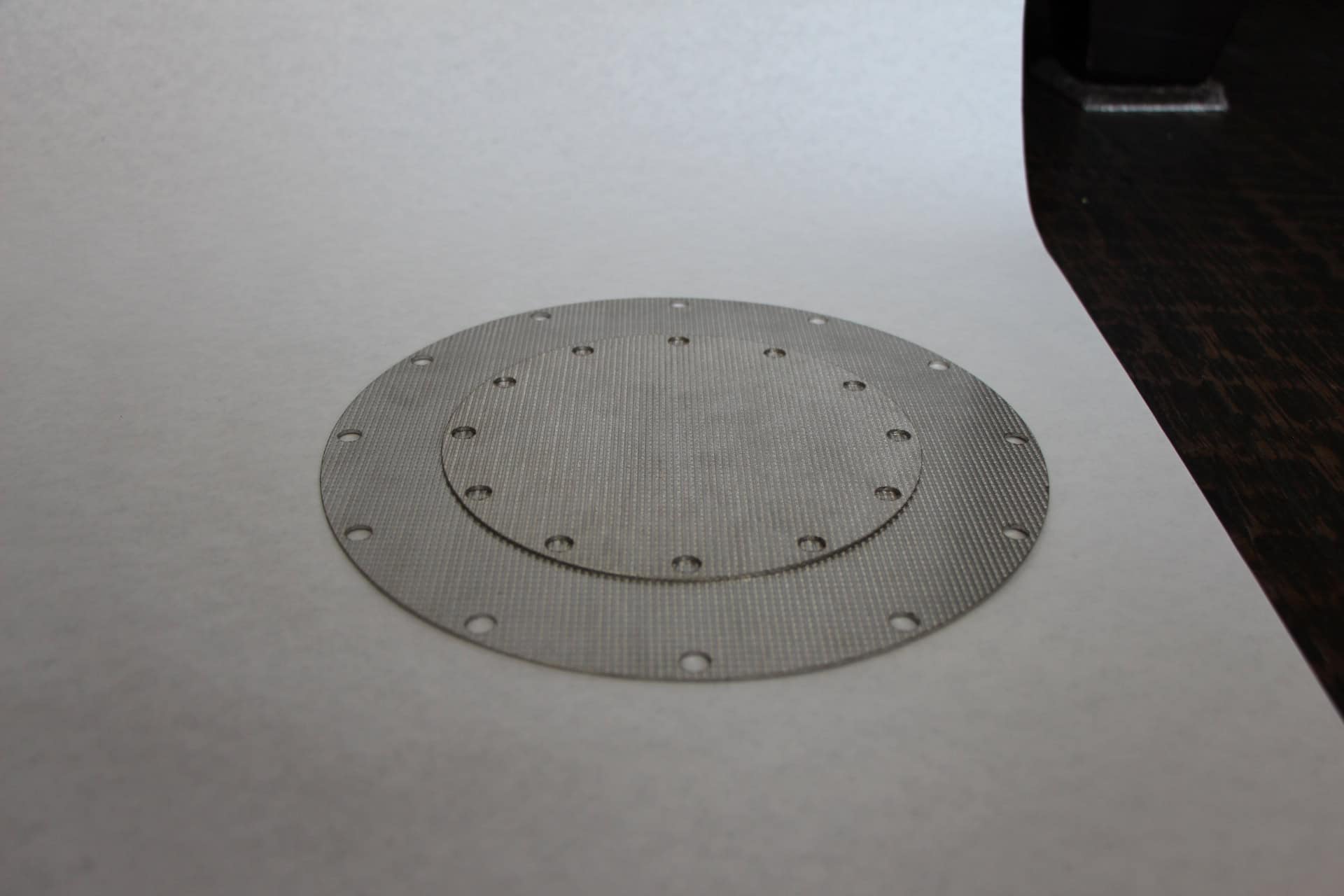

SINTERPORE® is available in 2-layer and 3-layer composite structures depending upon flow requirements. Each layer in the laminate performs a specific function in the structure. Heavy meshes provide strength and support to finer meshes which provide flow distributrion and flow barriers.

(SCFM/SF @ 2” W.C.)

(inches)

Engineered Pore Structure and Flow Dynamics

In addition to the standard SINTERPORE® low perm and high perm media, custom designs can be specified for almost any application. Strength, pore size, porosity, tortuosity, permeabiilty and edge flow resistance all can be designed to a given specification.

Porous Metal Filters is ISO 9001 Certified, and all our products are manufactured to the highest quality standards. Our staff is available to help you design the wire filtration product that will meet your design requirements and budget. Contact us today for more information about our products.

PMF Brochures and Product Literature

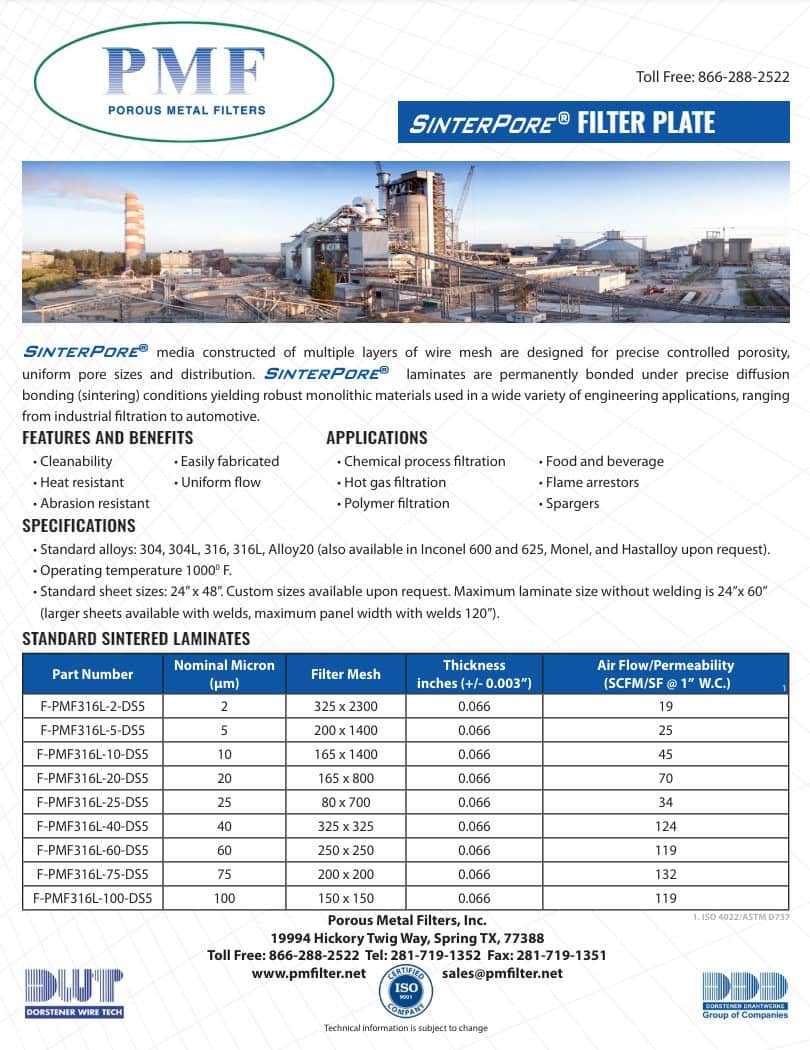

Filter Plate

2-page flyer with features and benefits, applications, and specifications (PDF)

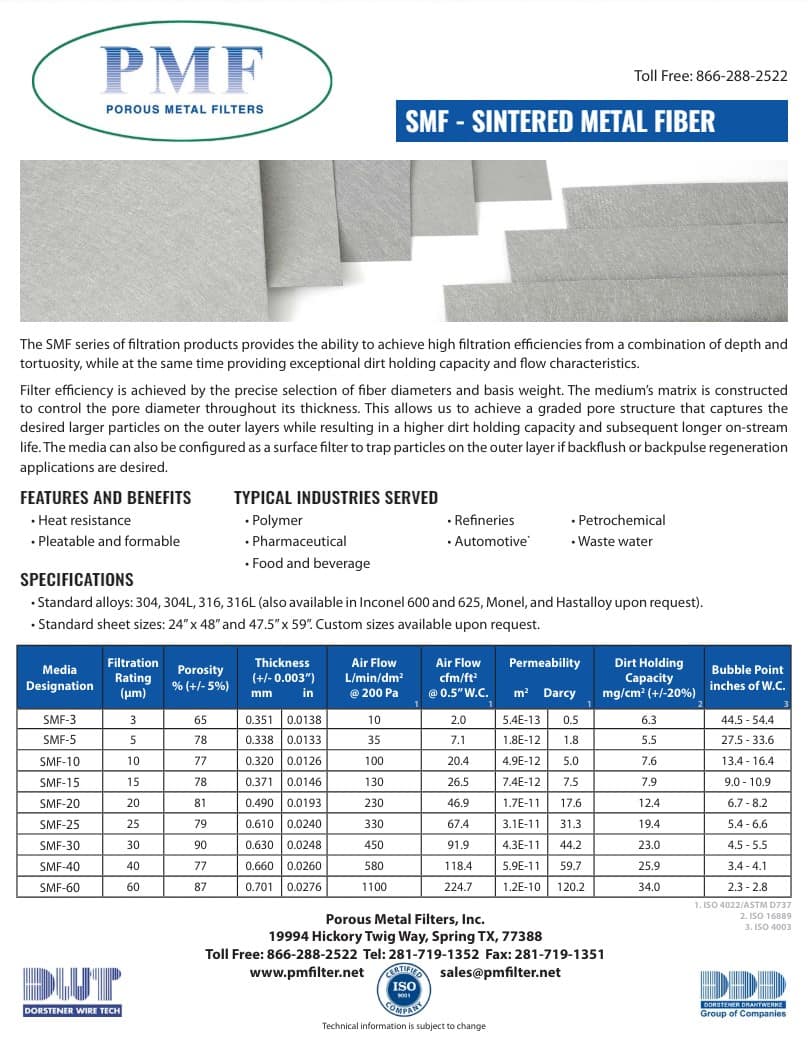

Sintered Metal Fiber

2-page flyer with features and benefits, applications, and specifications (PDF)

Metallic Filter Cartridges

2-page flyer with features and benefits, applications, and specifications (PDF)

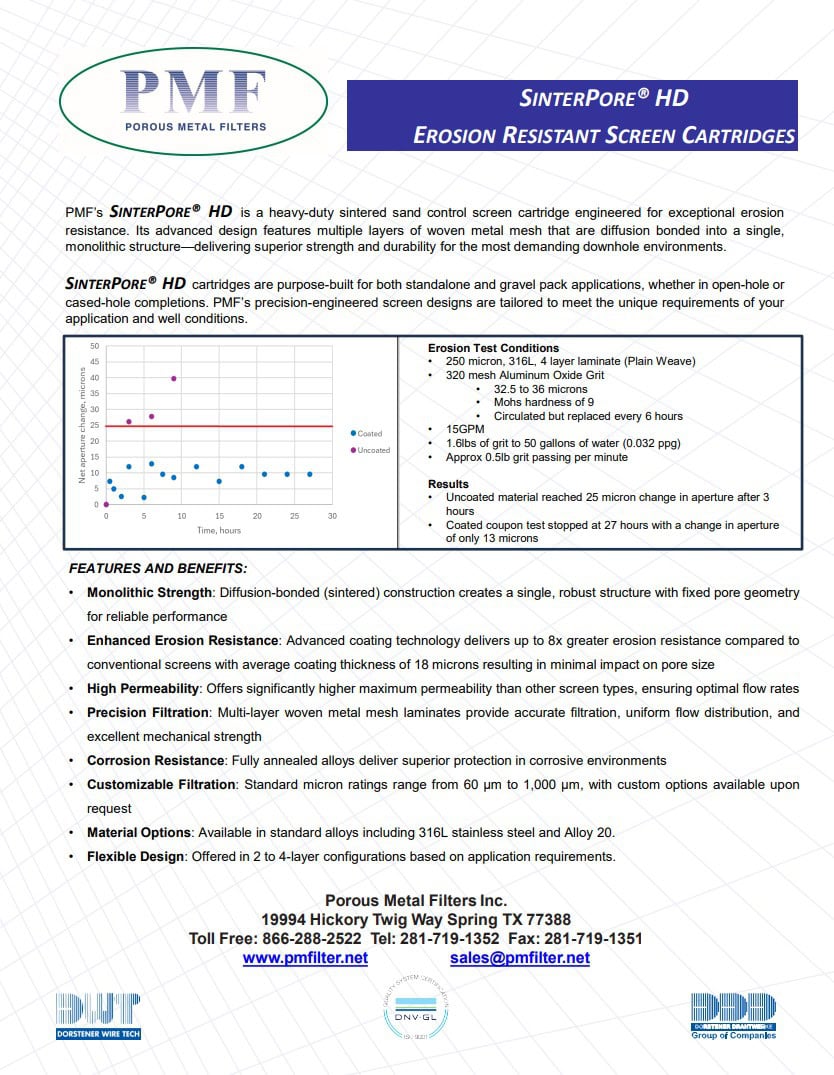

SinterPore® HD Erosion Resistent Screen Cartridges

1-page flyer with features and benefits, and specifications (PDF)

Fluidizing Media

2-page flyer with features and benefits, applications, and specifications (PDF)

Polymer Filtration

2-page flyer with features and benefits, applications, and specifications (PDF)

Power Generation

2-page flyer with features and benefits, applications, and specifications (PDF)

Ballast Water Filters

2-page flyer with features and benefits, applications, and specifications (PDF)

Your One-Stop Solution for Advanced Filtration and Metal Fabrication

We invite you to explore and discover how PMF can transform your filtration and separation challenges into opportunities for growth and success. Join us on this exciting journey as we reshape industries, one innovative filter at a time. Together, let's unlock the true potential of porous metal filtration. Give us a call, stop by for a free tour of the facility, or fill out our contact form and we'll gladly assist you.

Find Exactly What You Need

COMPANY

INDUSTRIES & APPLICATIONS

Automotive

Bulk & Powder Handling

Chemical Processing

Chromatography

Crude Oil Processing

Filtration Industry

Fuel Cells & Re-Formers

Gasification

Hot Gas Filtration

Industrial Filtration

Industrial Water Management

Irrigation Filtration

Liquid Filtration

Noise Abatement

Oil & Gas

Pharmaceutical

Plant Oil Extraction

Power Generation

Renewable Energy

Aerospace Filters

Ballast Water Filters

Chemical & Industrial Spargers

Chromatography Frits

Demineralizer Filters

Flame/Spark Arrestors

Flood Filters

Fluidizing Media

Gasification Filters

Hot Gas Filters

Irrigation Filters

Metallic Filter Cartridges

Metallic Memberane Support for Hydrogen

Nutsche Filters

Porous Metal Plate

Sand Screens

Sintered Metal Fiber

Sintered Wire Cloth

Temporary Strainers & Baskets

CAPABILITIES

Porous Metal Filters provides solutions for industrial filtration, separation, flow control, noise reduction, powder fluidization, and other applications through our SINTERPORE® brand of diffusion bonded (sintered) porous metal materials. Porous Metal Filters’ goal is to utilize its extensive experience to promote porous metal filters for the next generation of advanced filtration and separation products.

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(833) 707-9222 toll free

(281) 719-1352 local

(281) 719-1351 fax