PRODUCTS

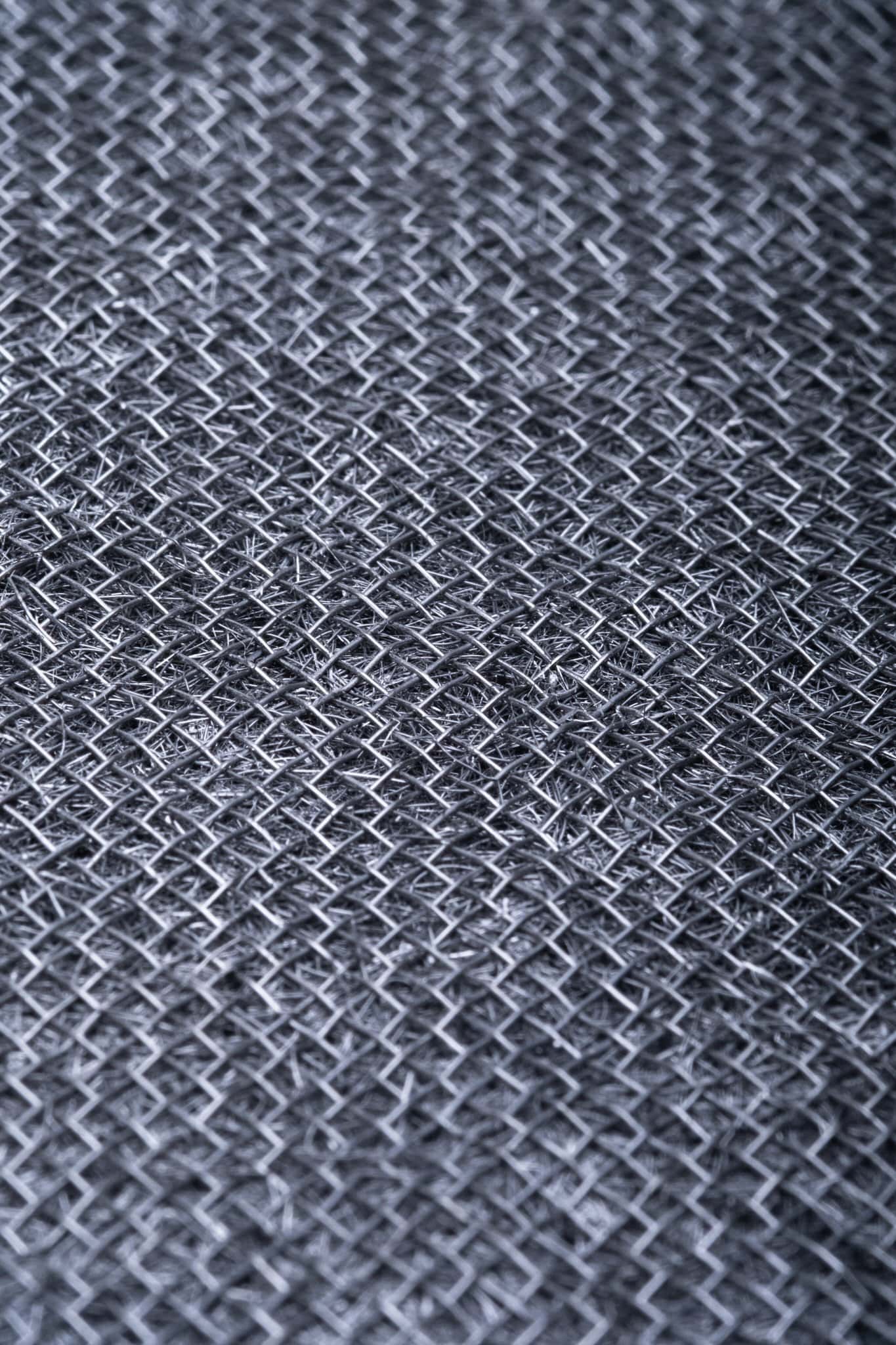

Sintered Metal Fiber

Diffusion Bonded / SinterPore™ Sintered Metal Fiber

The SMF series of filtration products provides the ability to achieve high filtration efficiencies from a combination of depth and tortuosity, while at the same time providing exceptional dirt holding capacity and flow characteristics.

Filter efficiency is achieved by the precise selection of fiber diameters and basis weight. The medium’s matrix is constructed to control the pore diameter throughout its thickness. This allows us to achieve a graded pore structure that captures the desired larger particles on the outer layers while resulting in a higher dirt holding capacity and subsequent longer on-stream life. The media can also be configured as a surface filter to trap particles on the outer layer if backflush or backpulse regeneration applications are desired.

Diffusion Bonded / SinterPore™ Sintered Metal Fiber products from Porous Metal Filters are used in many industries including Bulk and Powder Handling, Chromatography, Filtration Industry, Gasification, and Plant Oil Extraction.

mm (in)

L/min/dm² @ 200 Pa

cfm/ft² @ 0.5” W.C.

m² (Darcy)

mg/cm² (+/-20%)

inches of W.C.

Coil Sintering is a process that utilizes time, temperature, and atmosphere to secure or stick intersections of the wire mesh. The mesh can be calandered prior to heat treating to aid in bonding. The process produces a stable, secure mesh that is ideal for deep drawing and or reducing the risk of loose wire’s loose. This product is only available in single layer options.

SinterPore™ Sintered Metal Mesh provides many additional benefits when compared to traditional wire cloth.

- Diffusion bonded wire cloth can be fabricated in single or multiple layers. Multiple layer assemblies provide enhanced mechanical properties for filters and harsh environment applications.

- Sintered wire mesh is stable, making it ideal for mesh with a high percentage of open area or that requires a secure pore size.

- SinterPore™ sintered mesh is easy to fabricate and produces a stable, strong product. It can be constructed as a depth filter media, providing excellent filtration properties. It is an excellent material to use for products that require controlled permeability.

- Sintered wire mesh can be cleaned and re-used for many applications.

- Diffusion bonding locks and secures all wire in the mesh, eliminating loose wires and increasing the stability of the cloth. It can be used for small parts and special shapes without losing shape or loose wires. Traditional wire cloth can become loose and ineffective over time.

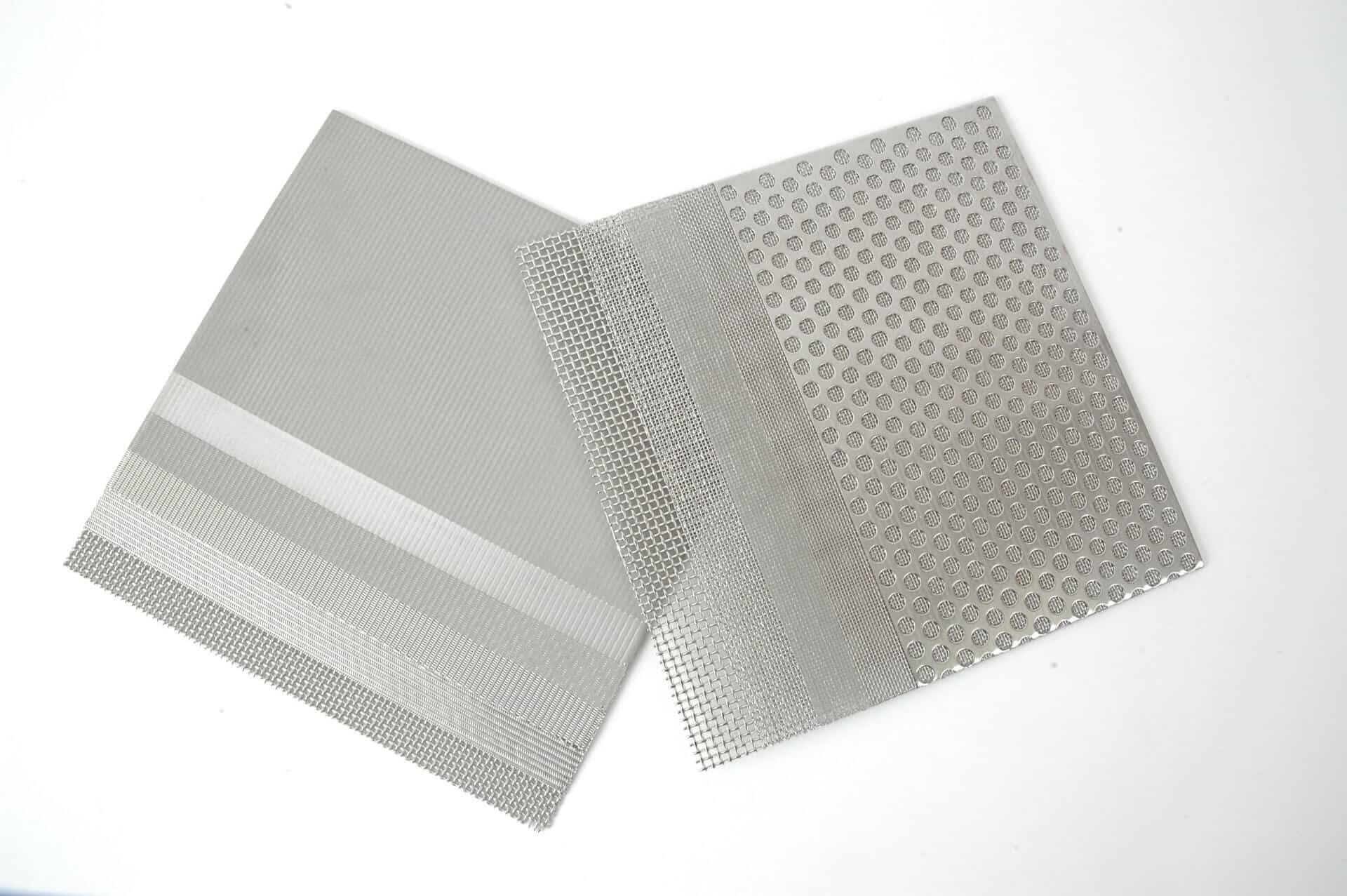

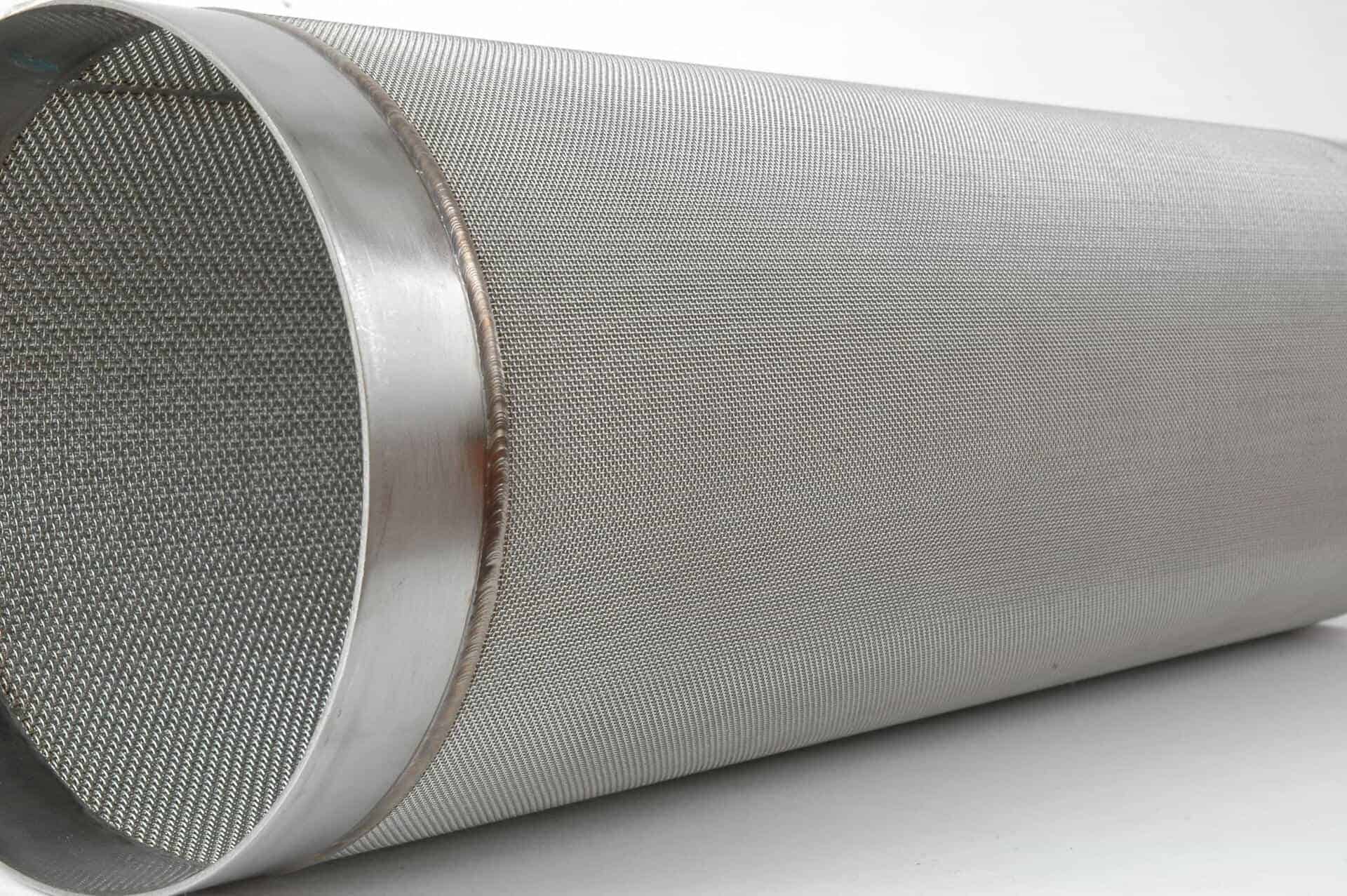

Definition of Sintered or Diffusion Bonded Wire Mesh:

Stainless Steel Sintered Wire Mesh is a filtering cloth made by pressing multi-layer woven wire cloth, then sintered together in a vacuum furnace. This kind of filtering cloth is much better than common metal woven wire mesh with good strength, hardness and good positioning of opening. Its comprehensive property is superior to sintered metal powder and porcelain. The major characteristics are: excellent strength, no inner support is required for making filter elements, no material, easily repeated cleaning, long lifespan and good anti-corrosion.

What Are Sintered Mesh Laminates?

Fine woven wire filter mesh provides micron-rated pore size but it is too thin and can be damaged. The best solution is to laminate the fine mesh to a coarser mesh supportive layer to provide increased strength and thickness. The common sintered wire mesh laminates are 5-layer or 6-layer, which is extensively used in filtration.

Sintered Metal Filter Elements Advantages

- Many elements can be cleaned and used multiple times.

- Sintered Wire Cloth elements are much stronger than non-sintered elements.

- Sintered elements have a stable pore geometry that is ideally suited for back flush filtration systems.

- Available in a wide range of alloys. Most common is 316Lss and 304Lss.

- Sintered Mesh Elements are available in a wire range of micron ratings (5 to 1000 micron) and can be custom designed to meet or exceed your filtration and performance requirements.

- Sintered Metal Filters are commonly used in Hot Gas Filtration, Polymer Filtration and Oil & Gas Filtration.

Sintered Metal Filter Wire Cloth Alloys

304 Stainless Steel Sintered Wire Cloth

Most common stainless alloy used in wire weaving. Excellent corrosion properties and can withstand temperatures of 1100 Degrees F.

304L Stainless Steel Sintered Wire Cloth

Similar properties as 304ss but lower carbon content to permit better welding.

316SS Stainless Steel Sintered Wire Cloth

Similar properties to 304ss but is stabilized by the addition of Molybdenum for increased resistance to chemical corrosion.

316L Stainless Steel Sintered Wire Cloth

Similar properties as 316ss but lower carbon content to permit better welding.

904L Stainless Steel Sintered Wire Cloth

Hight resistance to corrosion and rust for sea water applications.

Nickel 200 Sintered Wire Cloth

Used in applications where high corrosion properties are required. Some applications could include several chemicals, caustics, and certain organic acids.

Monel 400 Sintered Wire Cloth

One of the most widely used alloys for high corrosion resistance. Used in many food and chemical processes. Monel is a registered trade mark for International Nickel Co INCO.

All of our Sintered Metal Filters are available in a wide range of micron ratings and alloys. In almost all cases, sintered metal filters can be cleaned multiple times. Contact us today for a detailed quote or if you have any questions about our diffusion bonded sintered wire cloth capabilities.

Porous Metal Filters is ISO 9001 Certified, and all our products are manufactured to the highest quality standards. Our staff is available to help you design the wire filtration product that will meet your design requirements and budget. Contact us today for more information about our products.

PMF Brochures and Product Literature

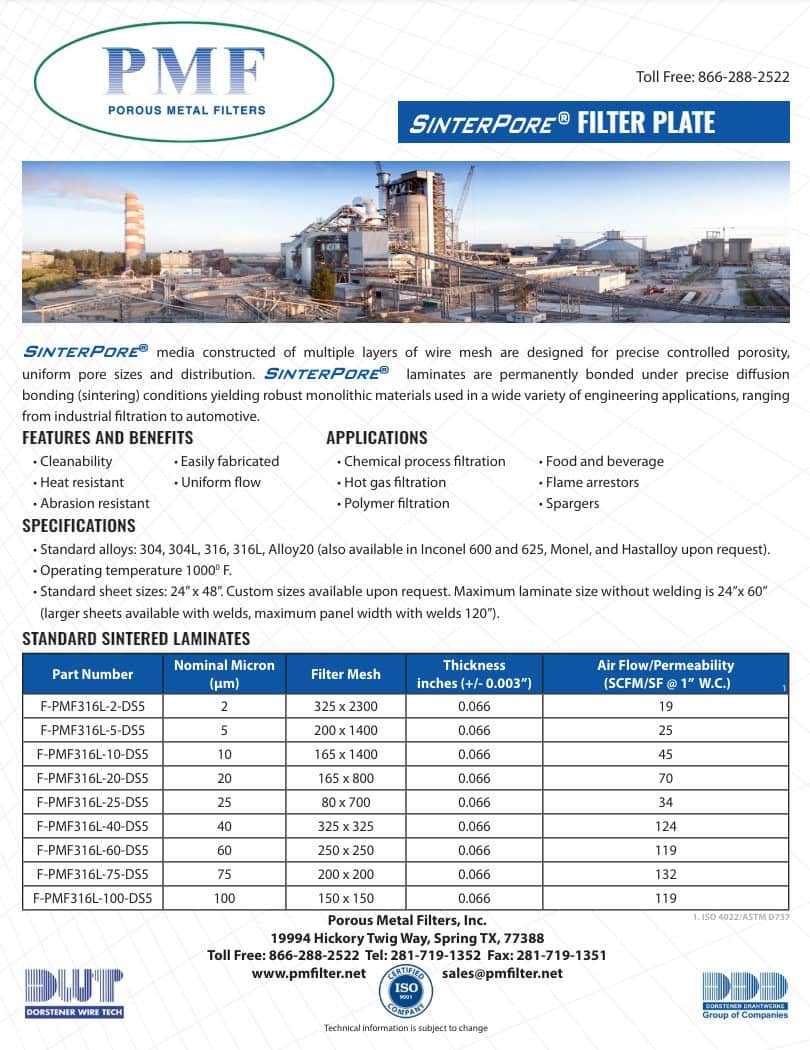

Filter Plate

2-page flyer with features and benefits, applications, and specifications (PDF)

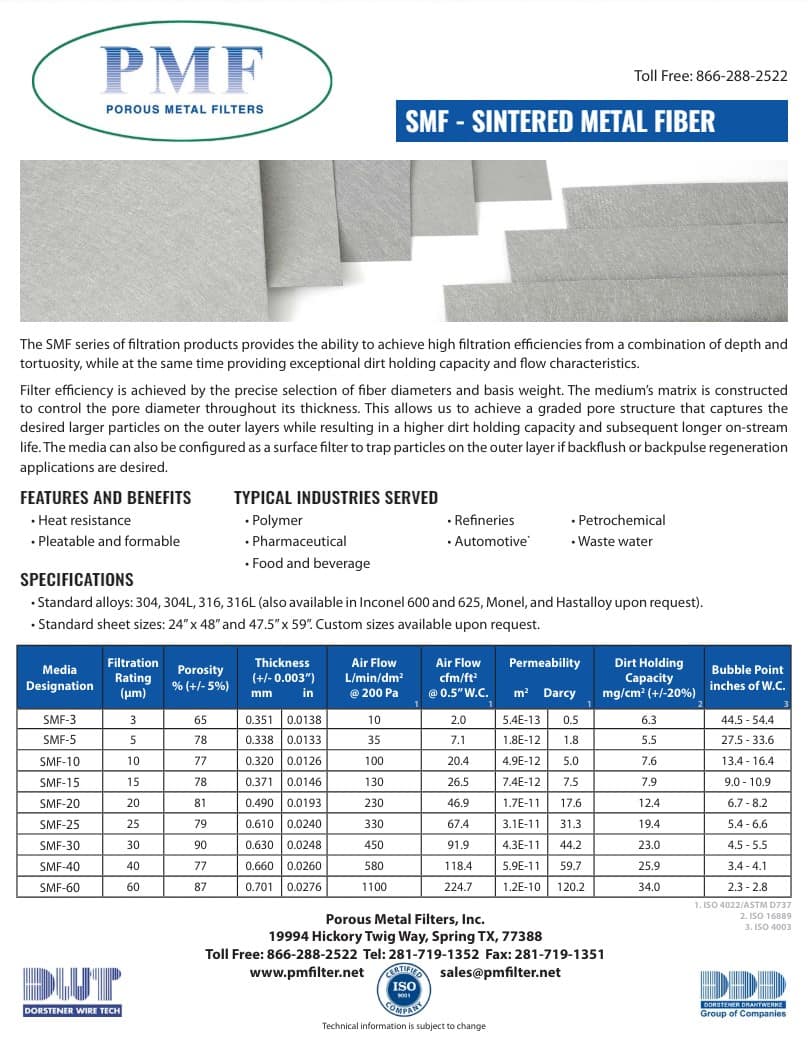

Sintered Metal Fiber

2-page flyer with features and benefits, applications, and specifications (PDF)

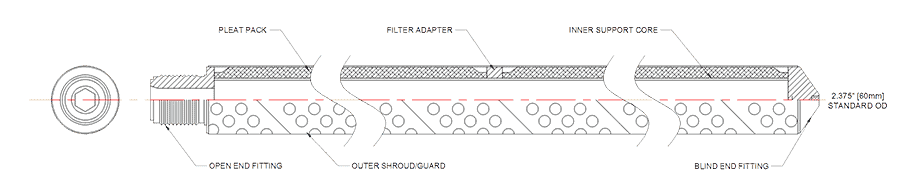

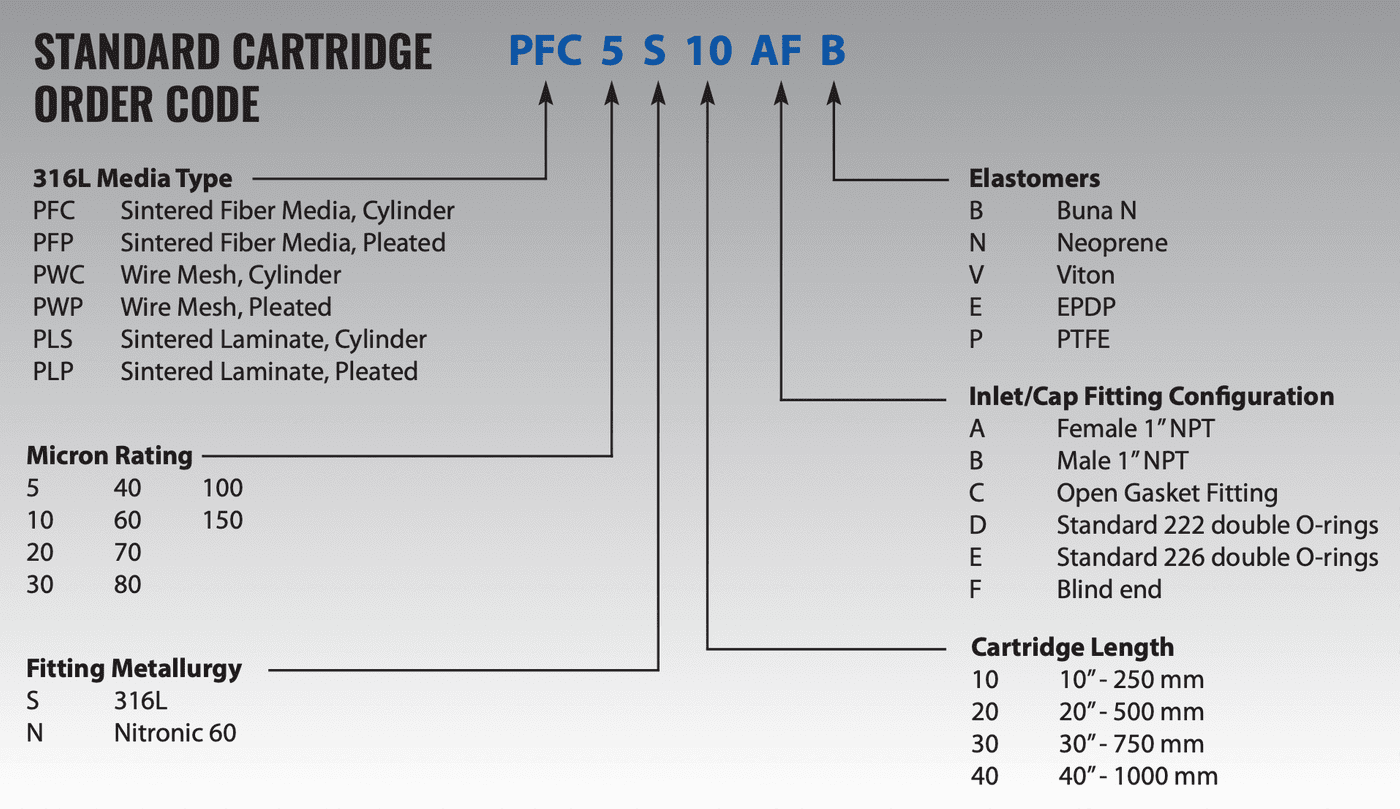

Metallic Filter Cartridges

2-page flyer with features and benefits, applications, and specifications (PDF)

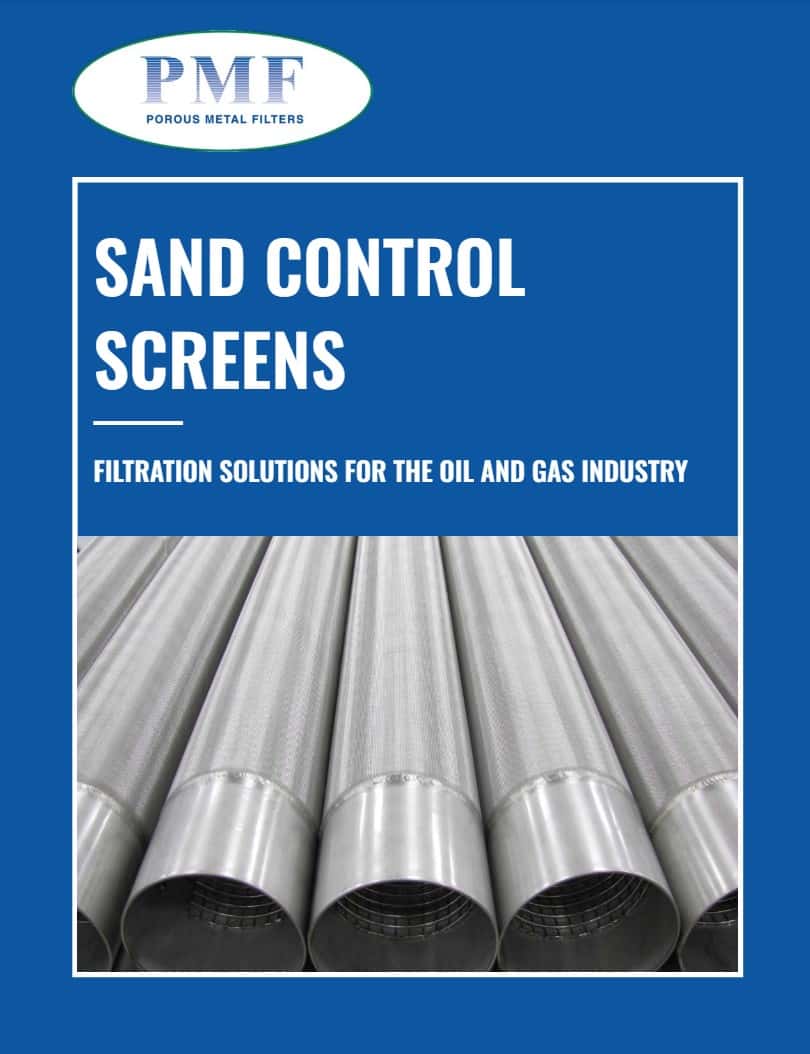

Sand Control Screens

4-page brochure with features and benefits, applications, and specifications (PDF)

Fluidizing Media

2-page flyer with features and benefits, applications, and specifications (PDF)

Polymer Filtration

2-page flyer with features and benefits, applications, and specifications (PDF)

Power Generation

2-page flyer with features and benefits, applications, and specifications (PDF)

Ballast Water Filters

2-page flyer with features and benefits, applications, and specifications (PDF)

Your One-Stop Solution for Advanced Filtration and Metal Fabrication

We invite you to explore and discover how PMF can transform your filtration and separation challenges into opportunities for growth and success. Join us on this exciting journey as we reshape industries, one innovative filter at a time. Together, let's unlock the true potential of porous metal filtration. Give us a call, stop by for a free tour of the facility, or fill out our contact form and we'll gladly assist you.

Find Exactly What You Need

COMPANY

INDUSTRIES & APPLICATIONS

Automotive

Bulk & Powder Handling

Chemical Processing

Chromatography

Crude Oil Processing

Filtration Industry

Fuel Cells & Re-Formers

Gasification

Hot Gas Filtration

Industrial Filtration

Industrial Water Management

Irrigation Filtration

Liquid Filtration

Noise Abatement

Oil & Gas

Pharmaceutical

Plant Oil Extraction

Power Generation

Renewable Energy

Aerospace Filters

Ballast Water Filters

Chemical & Industrial Spargers

Chromatography Frits

Demineralizer Filters

Flame/Spark Arrestors

Flood Filters

Fluidizing Media

Gasification Filters

Hot Gas Filters

Irrigation Filters

Metallic Filter Cartridges

Metallic Memberane Support for Hydrogen

Nutsche Filters

Porous Metal Plate

Sand Screens

Sintered Metal Fiber

Sintered Wire Cloth

Temporary Strainers & Baskets

CAPABILITIES

Porous Metal Filters provides solutions for industrial filtration, separation, flow control, noise reduction, powder fluidization, and other applications through our SINTERPORE® brand of diffusion bonded (sintered) porous metal materials. Porous Metal Filters’ goal is to utilize its extensive experience to promote porous metal filters for the next generation of advanced filtration and separation products.

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(833) 707-9222 toll free

(281) 719-1352 local

(281) 719-1351 fax